WTP Replacement

ArroPoint3 for Integration

A site had a nearly 20 year old Water Treatment Plant they wanted to replace. They selected the new vendor, and wanted to continue to have water production while the plant was changed out so as not to impact their business.

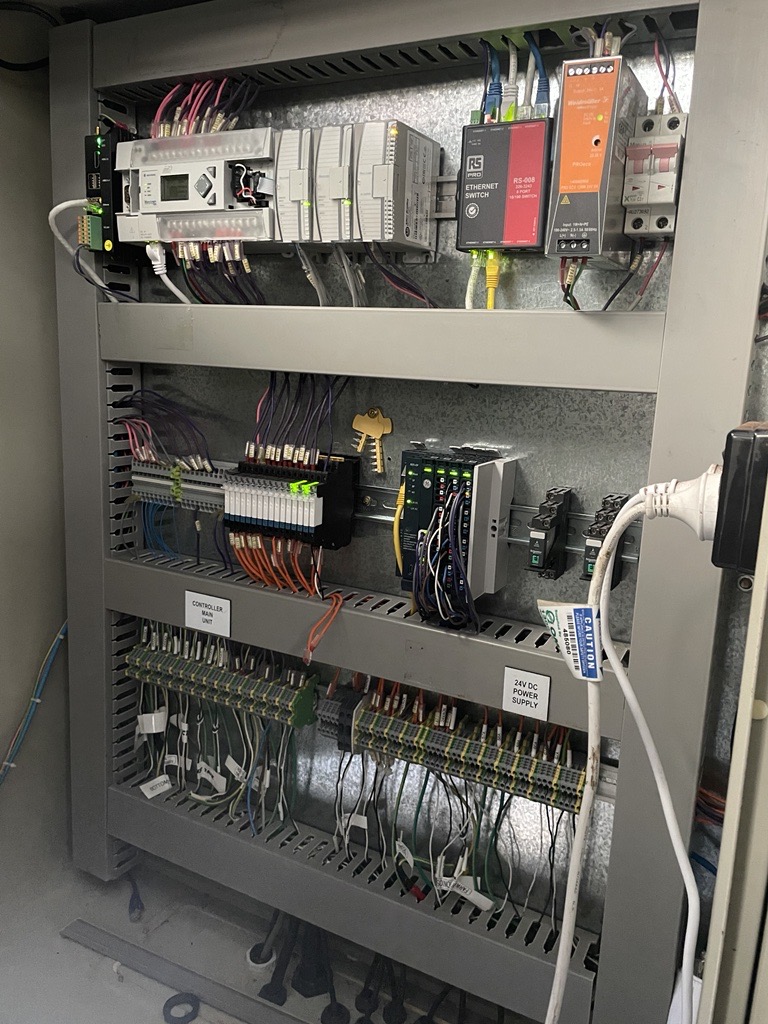

The new plant required communication with existing site infrastructure including existing PLCs and instruments. It had a different brand of PLC to the existing plant and was built to run “stand alone’.

ArroTek’s Scope

ArroTek were engaged to install a system capable of providing connections between the existing systems and the new plant, while at the same time enabling the old plant to continue to run while the new plant was being installed and commissioned. The old WTP skid, with its associated control cabinet and PLC were to be removed, while other off-skid components were to be migrated and retained.

ArroTek’s Solution

An ArroPoint3 unit was installed, and was capable of communicating with all the PLCs simultaneously (4 in total, as well as several VSDs). This made the migration much simpler..

The ArroPoint3 also enabled a common platform for monitoring and messaging across the site. Adding or subtracting plant became efffortless to the system. Logic via the PLC capabilities meant the new plant could remain “standard” while the extra functions required for continuity with existing components and instrumentation were readily able to be switched over very cost effectively and the old plant retired.

Easy configuration and migration

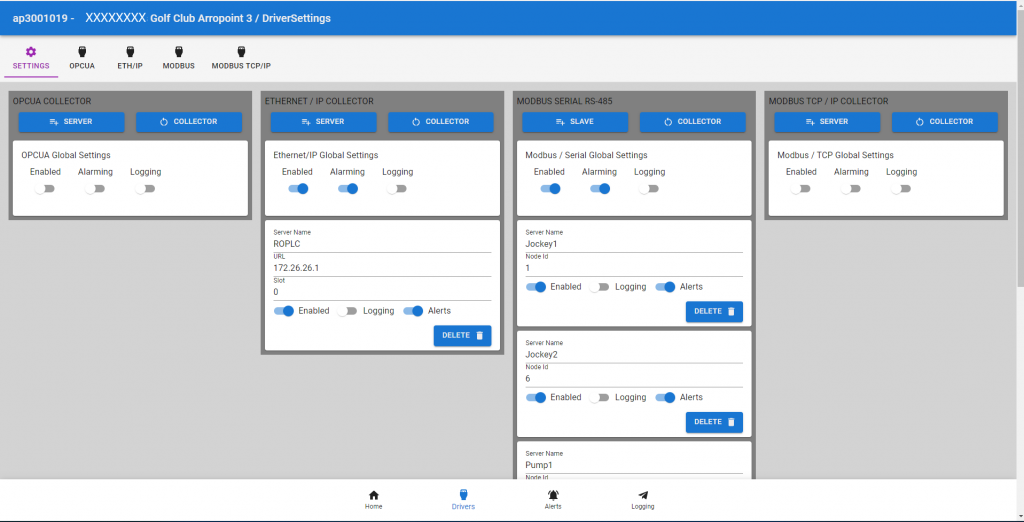

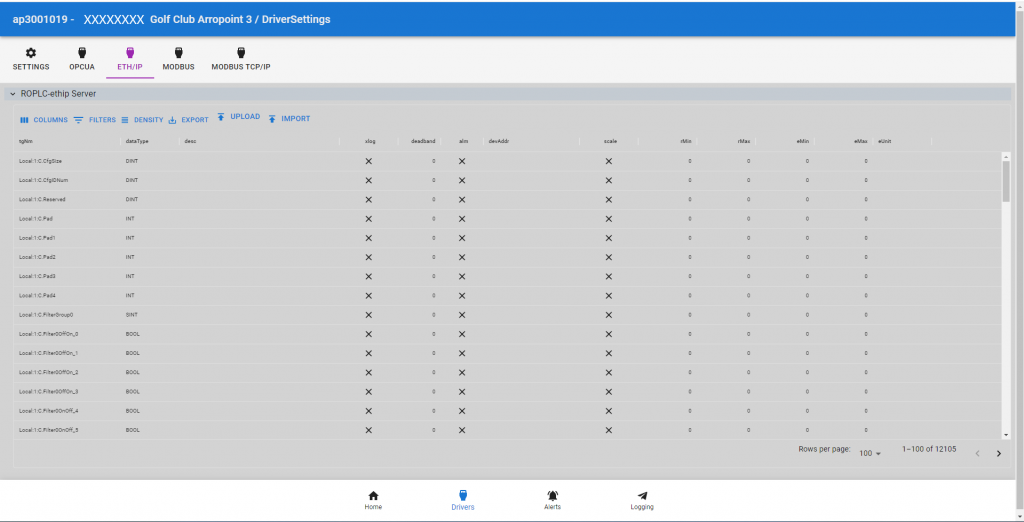

ArroSuite’s “Low touch” interface enables users to easily configure the device. This made connecting new and old devices quick & easy to the transfer the required machine state and instrument information to the new plant.

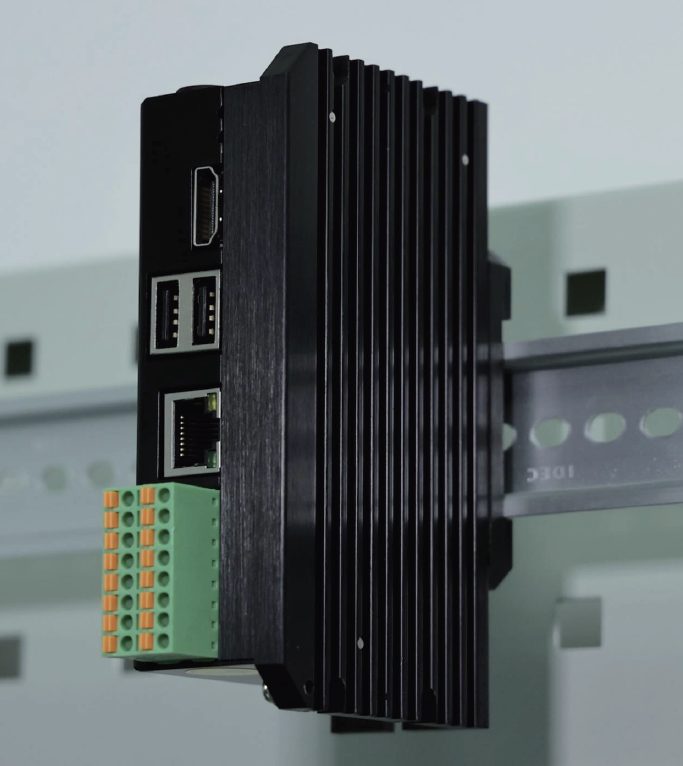

Multiple devices to one Arropoint

Remote I/O, RS232, RS485, Canbus, Ethernet, USB – a wide variety of cabling options enables multiple devices to connect.

Communication protocols include: OPCUA, Ethernet IP, Modbus TCP, Modbus Serial, MQTT, Canbus – with more being developed all the time.

Customise tag names and descriptions, value scaling and more.

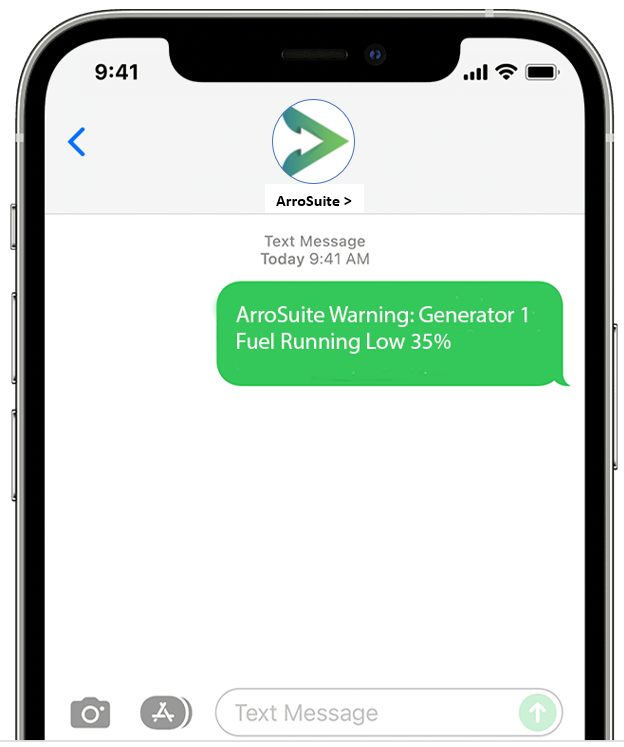

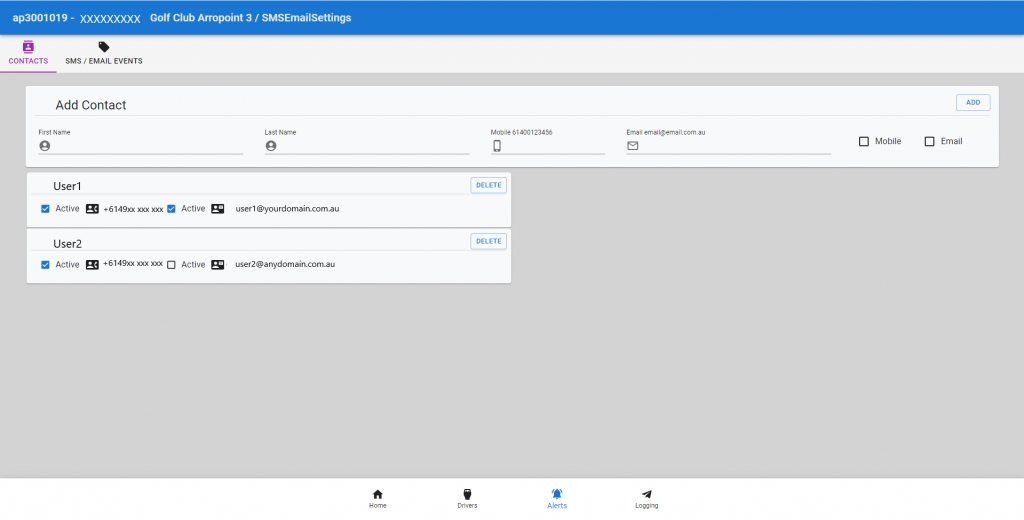

Enabling meaningful custom alarm messages to be sent, including the values read.

Manage your contact list and groups

Individual and group contacts can be readily configured for each individual alarm – enabling custom alarm escalations if the first contacts dont respond in time, a second group can be notified.